Description

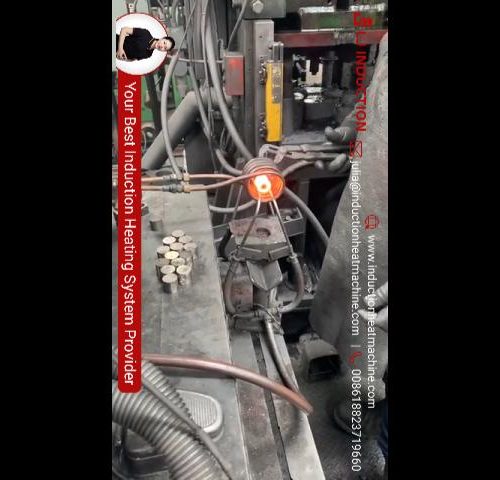

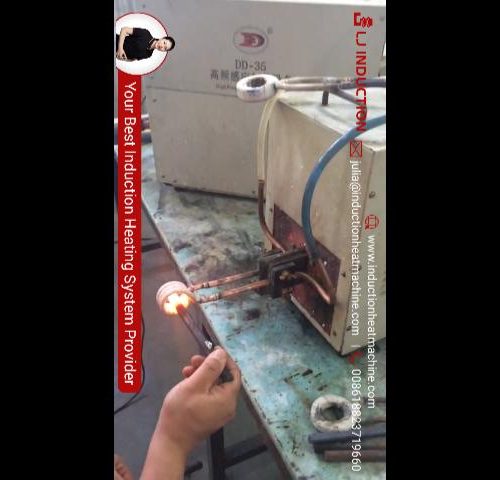

Induction Furnaces for Efficient Forging

LJ Induction designs and manufactures specialized induction heating furnaces for metal forging applications. Our induction forging furnace systems deliver rapid, uniform heating for maximizing productivity and part quality.

How Induction Forging Furnaces Work

The induction forging furnace contains one or more copper induction coils that surround the billet or part. The coils are powered by a medium frequency power supply, generating a magnetic field within the coils. This induces eddy currents in the conductive metal workpiece, heating the entire cross-section quickly and evenly to forging temperature.

Once the part reaches the Curie point temperature, it loses its magnetic properties, allowing the current to penetrate deeper for thorough, uniform heating. Water cooling prevents overheating of the induction coils.

Benefits of Induction Forging Furnaces:

– Increased productivity through fast heating cycles

– Energy efficiency by eliminating heat loss

– Consistent temperatures for high quality forgings

– Lower operating costs than combustion furnaces

– Flexible for automation or manual forging

LJ Induction engineers the furnace based on your material, billet sizes, production rate and other requirements. Contact us today for pricing info on induction heating furnaces for your forging needs.