Description

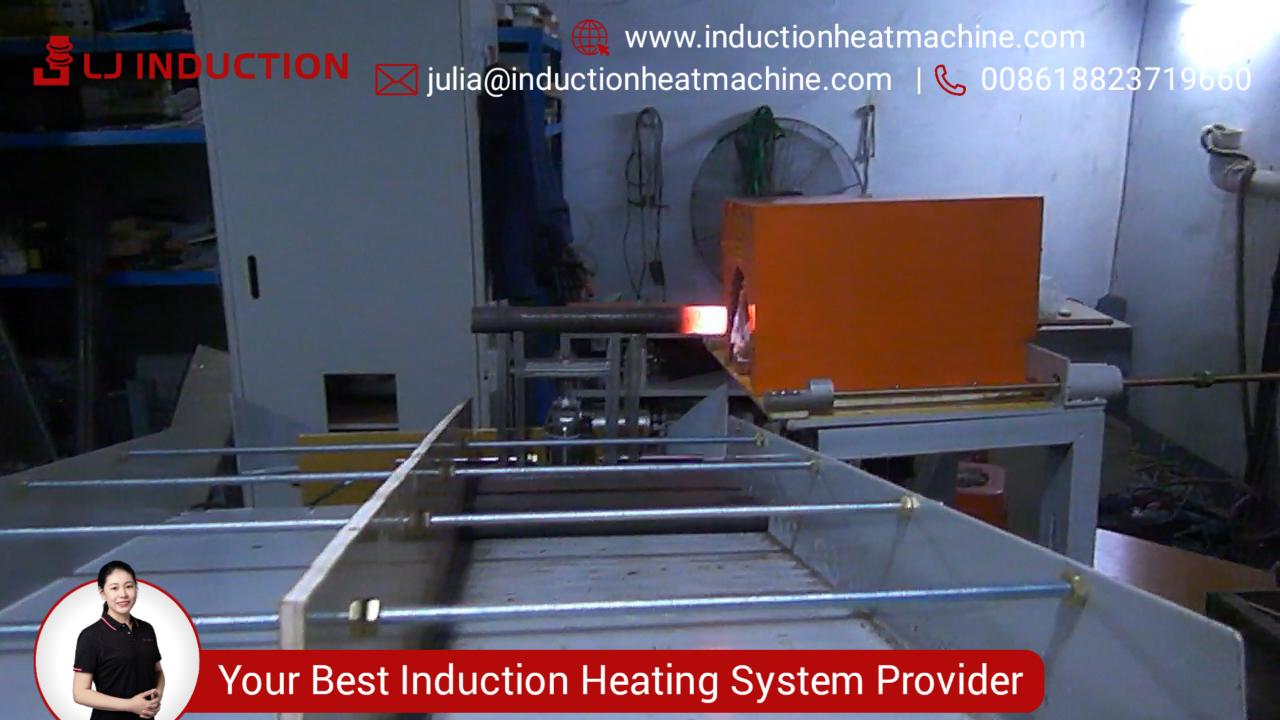

Induction Heating Forge Furnaces – Efficient Heating Systems For Forging

Induction heating is widely used in the forging industry for its fast, efficient and controllable heating capabilities. As a leading induction forging furnace factory in China, LJ Induction Heating specializes in designing and building customized induction heating forge furnaces that deliver rapid, uniform heating for metal forging applications.

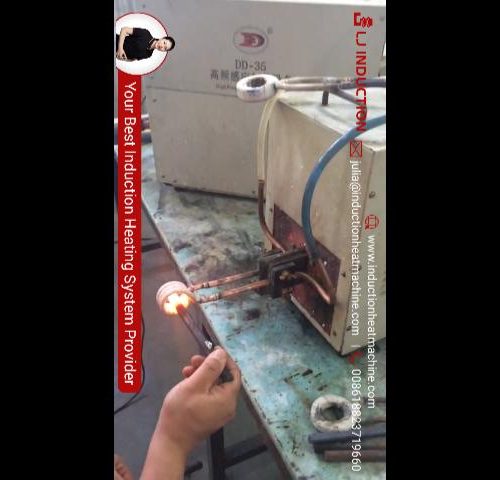

Our induction heating furnaces utilize the principles of electromagnetic induction to produce high power densities within the load. When alternating current flows through the induction coil, it generates a strong alternating magnetic field that induces eddy currents in conductive materials placed inside the coil. The eddy currents rapidly heat the metal through resistive Joule heating.

Compared to conventional furnaces, induction heating provides faster heating, improved energy efficiency, better control and consistency, reduced scaling and decarburization, and lower operational costs. Our innovative induction heating furnace designs are tailored to meet the unique needs of forging processes.

Features of Our Induction Forging Furnaces for Forging

– High power densities up to 300 kW/kg for rapid heating

– Maximum temperatures up to 2300°F (1260°C)

– Automatic control of heating patterns and temperature uniformity

– Minimal scaling, decarburization and oxidation

– Compact, modular designs for easy installation

– Water-cooled induction coils and components

– Energy-efficient power supply with power factor correction

– PLC-based control system with HMI touchscreen

Our induction heating forge furnaces are available in a range of standard capacities from 100 kg to 5000 kg. We also offer custom-engineered solutions for large forging ingots and complex geometries. The furnaces can be designed for batch or continuous processes.

Common applications include:

– Billet and bloom heating

– Bar, rod and tube heating

– Forging ingot heating

– Preheating prior to ring rolling

– Austenitizing and homogenizing

Why Choose LJ Induction Heating?

With over 20 years of experience manufacturing induction heating equipment, LJ Induction Heating is a trusted partner known for its expertise, quality and service. Our induction heating systems are used worldwide by leading companies in the forging, heat treating, and metals industries.

We have the engineering know-how to provide the optimal induction heating solution for your specific needs. Our in-house capabilities include:

– System design, simulation and analysis

– Production of induction power supplies up to 10 MW

– Fabrication of furnaces and heating equipment

– Integration of PLC-based control systems

– Testing, installation and maintenance services

Contact LJ Induction Heating today to discuss your induction forging furnace requirements. We will work closely with you through the entire process from initial consultation to installation and beyond. Call us now or email suri@inductionheatmachine.com to get started on your next induction heating project.

-500x480.jpg)