Description

Induction Hardening of Steel: 1045, 4140, and More Grades

Introduction :

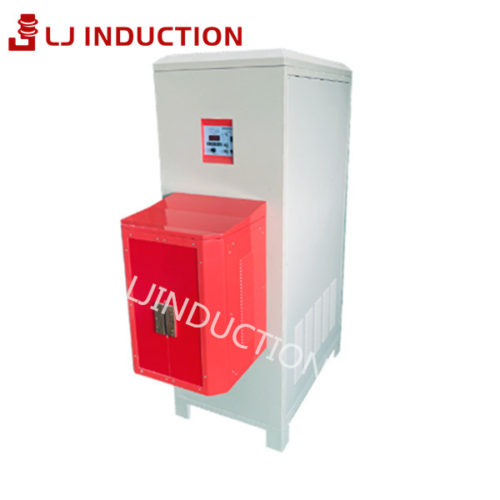

Welcome to LJ Induction, a renowned heating machine factory with two decades of experience. Explore our top-notch induction hardening machines, specially designed for steel components. Induction hardening of steel, including popular grades like 1045 and 4140, enhances metal parts’ mechanical properties and wear resistance. With our advanced technology, we achieve precise surface hardening and selective hardening results, ensuring optimal case depths and superior performance for various steel grades.

LJ Induction takes immense pride in our expertise in induction hardening of steel. Our cutting-edge machines are tailored to meet the diverse needs of steel components, offering reliable and efficient surface hardening solutions.

Understanding Induction Hardening of Steel:

Induction hardening is a surface hardening process where steel components are heated through an induction coil. The rapid heating and cooling process leads to martensitic transformation in the surface layer, improving mechanical properties and wear resistance.

Enhancing Steel Grades: 1045 and 4140:

Our induction hardening technology is particularly effective for popular steel grades 1045 and 4140. By selectively hardening specific areas, we can tailor the hardness and mechanical properties to meet your requirements.

Precise Surface Hardening with Induction Coil:

Our induction hardening machines utilize advanced induction coils to achieve precise and uniform heating. This ensures consistent results, even for complex geometries and various steel grades.

Optimal Case Depths and Mechanical Properties:

Induction hardening of steel results in optimal case depths, ensuring a hardened surface layer with improved mechanical properties. This leads to enhanced durability and resistance to wear and fatigue.

Heat Treatment for Superior Performance:

Induction hardening is a crucial heat treatment process for steel components. By carefully controlling the heating and cooling rates, our machines ensure the steel achieves the desired hardness and mechanical characteristics.

Selective Hardening for Specific Applications:

With our induction hardening technology, it’s possible to selectively harden only certain areas of a steel component, providing tailor-made solutions for different applications.

Advantages of Rapid Cooling in Induction Hardening:

Rapid cooling during the induction hardening process prevents the formation of undesirable phases in the steel, resulting in improved microstructure and mechanical properties.

Surface Hardening for Improved Wear Resistance:

Induction hardening creates a hardened surface layer that significantly enhances wear resistance, making steel components suitable for harsh and abrasive environments.

Applications of Induction Hardened Steel Components:

Induction hardened steel components find applications in various industries, including automotive, aerospace, manufacturing, and more, where durability and reliability are essential.

Conclusion:

LJ Induction offers state-of-the-art induction hardening solutions for steel components, including grades 1045 and 4140. With precise surface hardening and selective hardening capabilities, our advanced machines ensure optimal case depths and enhanced mechanical properties, making your steel components more robust and wear-resistant.